The CropEnergies Group has several production sites in Europe. In Wanze, Wilton and Zeitz, high-quality products are manufactured from plant-based raw materials. In Loon-Plage, ethanol (raw alcohol) is refined for various applications.

You can find more details about our individual sites here.

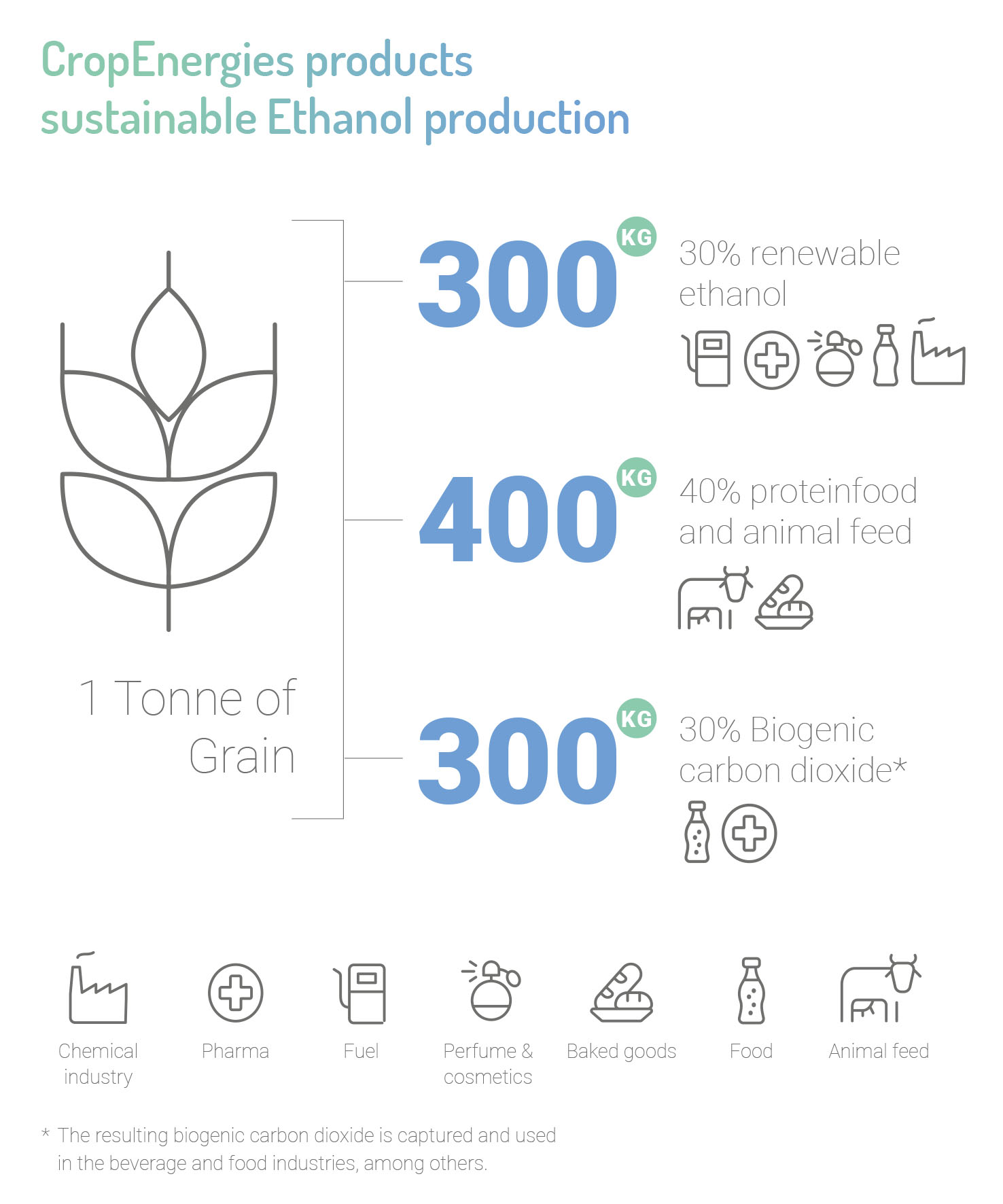

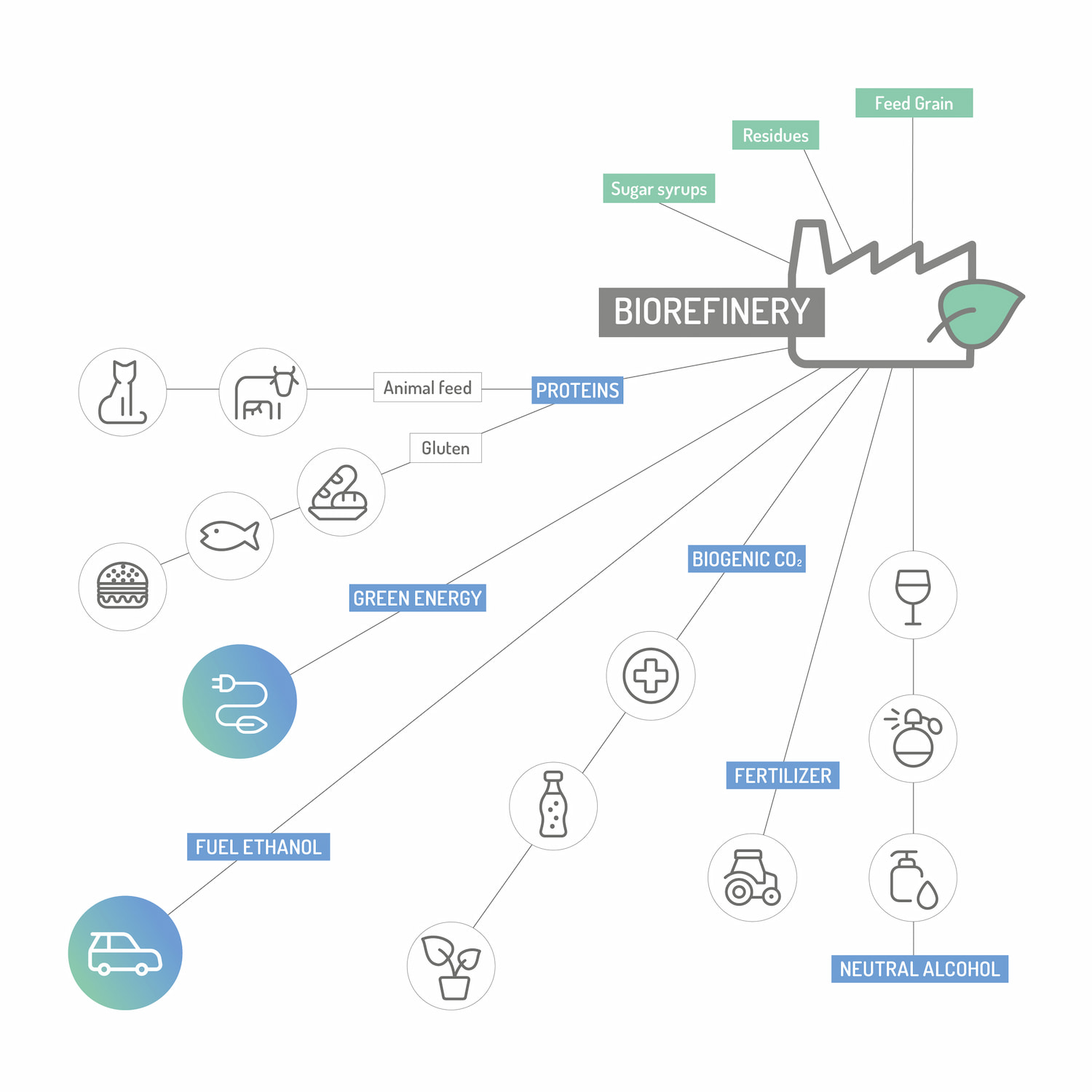

CropEnergies' biorefineries mainly process grain (i.e. wheat, corn, barley), but also starch and sugar-containing residues from Südzucker Group production plants.

You can find more information about our raw materials here.

Schematic diagrams of the respective production processes can be found here.

CropEnergies has a quality assurance system that regularly monitors product quality with the aid of modern process control technology and laboratory analyses. The quality management system covers all aspects of product safety and serves as an organizational and communication tool within the company, but also vis-à-vis suppliers and customers. Continuous improvement and a constantly improving product safety culture are important objectives of this quality management system.

Other key elements of quality management are long-term supplier relationships and detailed raw material specifications, qualified employees, safe production processes and close coordination with customers. The system also includes consistent complaints management for the entire product portfolio as an additional tool for the continuous improvement of processes and products.

You can find more details about our products here.

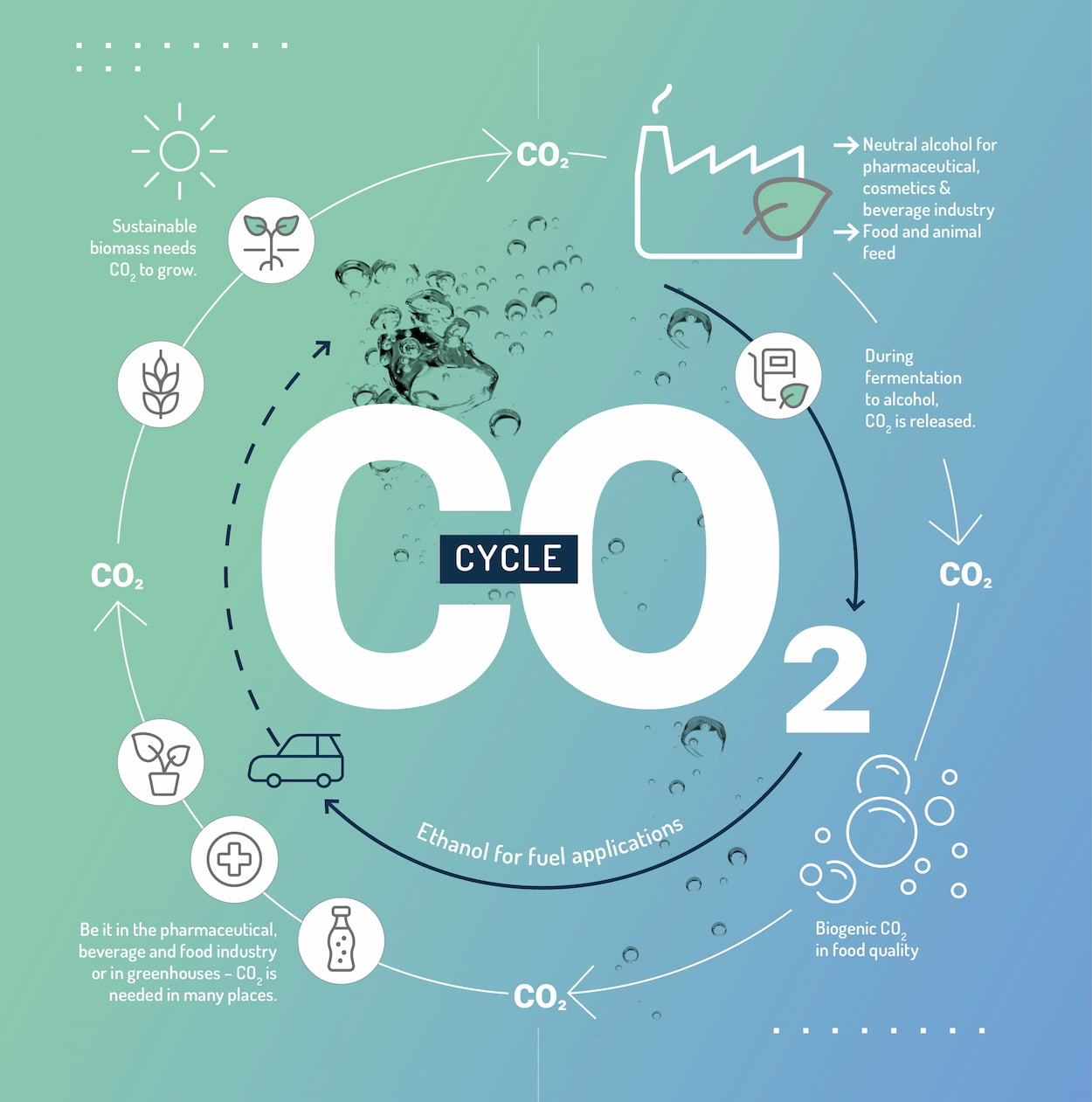

Our biorefineries work according to the principle of the circular economy, i.e. the material cycles are closed as far as possible and pollutants are discharged in a controlled manner so that waste can be made available to the economy again as secondary raw materials.

It is essential that the biomass used is utilized as completely as possible. This results in numerous products such as neutral and fuel ethanol, food and animal feed as well as biogenic carbon dioxide.

All CropEnergies products are characterized by the fact that they are produced from renewable raw materials, especially agricultural and non-agricultural biomass.

Biomass is a renewable raw material and, as a natural carbon sink, an important part of the carbon cycle. In the course of photosynthesis, CO2 is removed from the atmosphere and converted into carbon, among other things. The use of biomass for energy is CO2-neutral, as the maximum amount of CO2 released is equal to the amount previously absorbed during growth.

Due to the biogenic carbon source, our products contribute to defossilization, i.e. the move away from fossil raw materials. After all, industry will not be able to do without carbon in the future.